At first glance, platooning looks a bit peculiar- a few trucks traveling in line, unnaturally close to each other. But actually, what happens in truck platooning is much more complicated than it appears. It is considered as a significant part of a pilot program that has the potential to revolutionize the way goods are delivered around the globe, increase safety, save energy and provide cost benefits.

Report says, on January 15, 2019, at the annual meeting of the Transportation Research Board, the industry and government experts from around the world have outlined their forthcoming plans to pave the way for platooning that utilizes vehicle-to-vehicle communications for forming convoys of two or more closely spaced trucks with streamlined braking and acceleration.

Because of the significant role of platooning in the fleet management process and its possible growth in the near future, many companies have started exploring ways to deploy this procedure in their freight operations. But is it the right decision to take? Well, that is what will be discussed in today’s post.

In this post, the discussion will be about what impact platooning leaves on truck drivers and fleet services. Also, what developments are currently associated with truck platooning and how it will bring revolution in the fleet management operation. And at the end, you will realize that if you deploy platooning in your freight operation, it will certainly be the right decision. But before diving into that topic, let’s talk about what truck platooning actually is.

So, without further ado, let's start the discussion.

What Is Truck Platooning?

When two or more trucks move in a convoy, utilizing connectivity technology and automated driving support systems, the entire process is called truck platooning. All the trucks in platooning maintain a specific set of distance between each other whenever they get connected for certain parts of a journey. There is one truck, positioned at the starting point of the platoon, where drivers stay in control throughout the journey, lead the entire platoon and navigate the route. Also, they can even take the decision of leaving the platoon and driving independently if needed. The drivers of the rest of the vehicles behind the leading truck are also responsible for steering and taking over the speed and braking as needed. But they also react and adapt to changes in the first truck’s movement, often performing little or no action. The virtual link allows all the vehicles in a platoon communicate with each other, enabling them to automatically work together, i.e. putting accelerator or brake together. The technology used in platooning spots and responds to slow or stopped vehicles ahead of the platoon and make an adjustment as required when any vehicle cuts in between the trucks in the platoon. In the near future, as the technology upgrades, the trend of driverless truck platooning may become more popular, requiring only a lead driver, or no human drivers at all.

Undoubtedly, truck platooning has myriad benefits in the process of fleet management. Let’s talk about what positive impact it leaves on the logistic services.

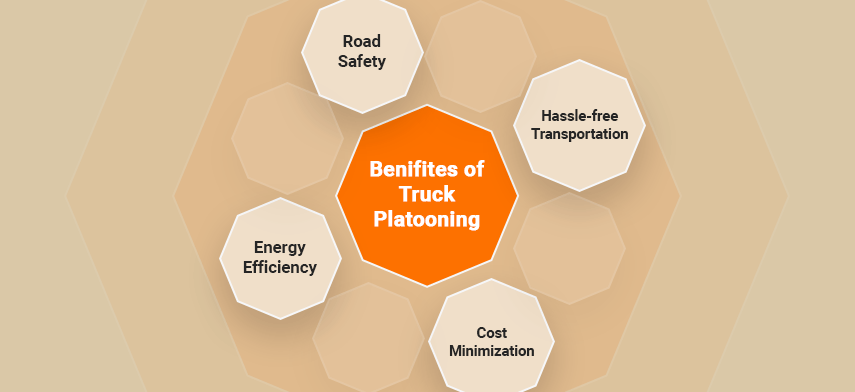

What Benefits Can You Get From Truck Platooning For Logistics Services?

- Road Safety

The major risk factors with traditional trucks are the reaction time and concentration of the drivers. Therefore maximum traffic accidents happen because of human error. Platooning helps in increasing the capacity of roads and decreasing the distances between the vehicles utilizing electronic and mechanical coupling. This capacity enables many vehicles to brake or accelerates simultaneously. These vehicles can brake immediately and such automatic brakes can react much quicker than a human. Therefore platooning improves safety and minimizes the possibility of collisions.

- Energy Efficiency

Truck platooning with its vehicles, trailer design, infrastructure etc. play a significant part as the transport industry’s integrated approach to further bringing down the CO2 emissions. In platooning, the trucks move while maintaining closer distance between each other at a smoother speed with less accelerating and braking as compared to conventional trucks on the road. This results in reducing fuel consumption and improving energy efficiency. According to a report ,“Platooning can reduce CO2 emissions by up to 16% from the trailing vehicles and by up to 8% from the lead vehicle.”

- Cost Minimization

Fuel cost covers a great amount of the overall operation cost of fleet services. As platooning has a significant role in reducing fuel consumption, it saves quite a lot in the fleet management cost. Also, in driverless truck platooning, autonomously driven trucks can save the cost of drivers.

- Hassle-free Transportation

Truck platooning uses the roads more effectively than any other conventional truck. All the trucks are driven at smooth speed being close to each other, making the traffic flow better, reducing tail-backs, and delivering goods in a speedy manner.

To sum up, the process of truck platooning has great potential to optimize fleet service and make transportation more efficient than ever. Also, it saves cost without sacrificing safety. Therefore with well-implemented platooning, the logistics industry has a bright future in the coming years.

What Do You Need To Know About The Current Developments & Awaited Future Associated with Truck Platooning?

The latest developments in the truck platooning system include vehicle-to-vehicle (V2V) communication, vehicle-to-infrastructure (V2I) communication and satellite (GPS) communication. These developments have ensured secure connectivity between all the vehicles and other information networks in a platoon where freight fleet operators can easily monitor the transportation administrations. Also, the implication of cybersecurity in the automated platooning system makes it safe and secure. Other than these, there are some more advanced features brought into effective action in truck platooning, including adaptive cruise control, mitigation system, forward collision avoidance system, active braking system, and lane departure warning system. All these features if deployed in the vehicles properly, will allow them into the semi-autonomous level of driving and decrease the chances of accidents during the transit.

The wide benefits of truck platooning for the transport industry have the potential to be transformative, together with other developments in autonomous vehicle technology. It offers the opportunity to make the current operations better and capture new business that is the driving force in the logistics business. Therefore the global market for platooning will surely grow in the near future.

Wrapping it up,

Be it a large fleet company or an independent fleet planner, they all get great benefits from a well-planned platooning system. The implementation and evolution of truck platooning clearly say that it helps the entire transportation process become seamless while saving energy and cost. Certainly, there is more potential on the horizon. Every independent logistics manager has the opportunity to harness the maximum benefits of platooning for multiple companies. The more vehicles become available to this system, the more companies will get the chance to save money and make the roadways more efficient. And with collaboration like this, one can bring a smarter solution for fleet management needs and the future for the autonomous world.

Author's Bio